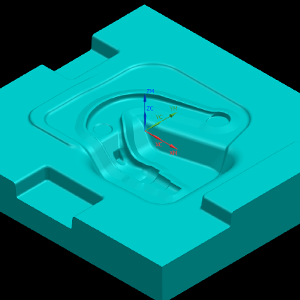

All of the MMF forging plants is equipped with in-house tool rooms. The Tool room is equipped with state of the art Vertical Machining centers for tool manufacturing. MMF has the capability to machine die blocks up to 3m in length.

Precision tool manufacturing is critical for quality forging. Understanding this, MMF introduced Vertical machining centers for tool machining way back in 1991 and is one of the first in the country to do so. Tool steel is procured from reputed international manufacturers from across the globe. Tools steels of several grades like H13, H11, and DIN 2714 are used based on the application.

Tool machining is done using state of the art Vertical Machining Centres for high speed die machining. The manufactured tools go through rigorous inspection process before being released for production. To optimize the material usage and improve the output of the tools, MMF introduced robotic die welding and surface treatment of the forging tools.